Carbon fibre is proving the key ingredient needed in new tanks for aircraft, ships and gas transport as the use of hydrogen as a greener alternative to fossil fuels edges closer to commercial use after decades of talk.

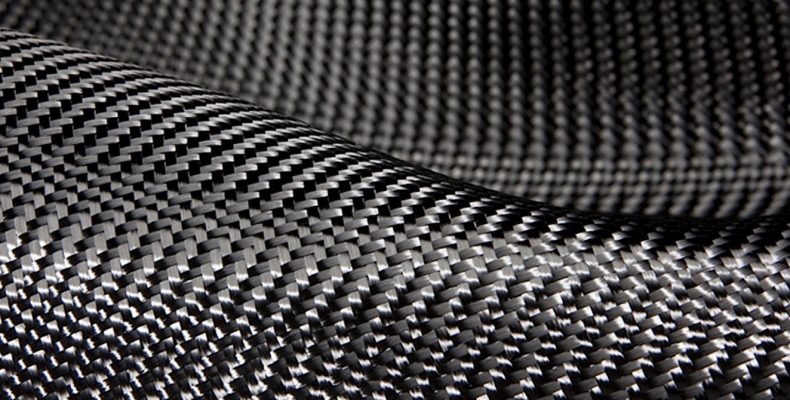

Carbon fibre-reinforced polymer pressure vessels for hydrogen storage are on the rise after hydrogen was identified by the European Commission (EC) as a key priority.

Earlier this month, the first sod was turned on the Hydrogen Test Bed project, a five-year $2.3 million industry-led new hydrogen research facility at Deakin University Warrnambool.

The facility will be used to investigate hydrogen compatibility in the existing reticulated gas network as Deakin’s Warrnambool campus transitions to 100% hydrogen.

Australia’s future hydrogen industry exports are estimated to be worth around $11 billion a year in additional GDP. The Australian Government has already committed more than $570 million to back this industry’s development.

Hydrogen can safely power many things that petrol, diesel and gas can without emitting carbon dioxide, yet its viability as a fuel source depends on the rapid development of transport, delivery and storage technologies.

Universal Hydrogen — co-founded this year by ex-CTO for Airbus Paul Eremenko and United Technologies – has created twin hydrogen storage tanks in a carbon fibre-reinforced polymer frame.

The company, which is considering partnering with a composite tank manufacturer, told CompositesWorld.com * the modules have been developed for 50-seat regional aircraft and feature tanks using carbon fibre to hold hydrogen gas, sitting within a lightweight composite frame.

The tanks will include an impermeable polymer liner wrapped with layers of dry carbon fibre braid. There is no need for resin as the liner addresses permeability, while the carbon handles axial loads and the outer layer and frame prevents damage, allowing weight and thickness to be reduced.

The planes can fly about 400 nautical miles with a 45-minute reserve so most flights can be done with a gaseous hydrogen system using carbon fibre reinforced polymertanks.

Shipping is also coming under regulations designed to reduce greenhouse gas emissions and a high-speed ferry utilising carbon fibre reinforced polymer is in the works at EC project SuperGreen, with Cimarron Composites cryogenic testing carbon fibre reinforced polymerpressure vessels developed with NASA.

LNG must be stored at a cryogenic -163°C and the idea is to modify aerospace technology for maritime applications.

The American Bureau of Shipping has granted approval in principle for Cimarron’s conceptual design of an ultralight, cryo-capable composite LNG tank which will provide weight savings of more than 85% versus a conventional metal tank.

Cimarron Composites founder and president Tom DeLay told CompositesWorld.com it is made with carbon fibre and an advanced thermoset resin using some resin infusion and wet filament winding.

“We formulate the resin ourselves using commercially available products and very tightly control the fibre and resin content as well as the tension during filament winding and oven cure cycle to prevent thermal stress. All of this adds to the mechanical performance of the tanks.’

– Tom DeLay, Founder, Cimarron Composites

“We are getting very large orders and all kinds of requests. We can see that, globally, a wide range of industries are investing seriously in hydrogen.”

In Australia, the government has just selected a consortium to deliver the ‘German-Australian Supply Chain Feasibility Study of Hydrogen produced from Renewables’ led by University of New South Wales (UNSW), Deloitte and Baringa Partners. This follows the signing of a landmark agreement between Australia and Germany in September to explore the potential for closer collaboration on hydrogen supply.

The consortium will begin work to identify barriers and the optimal approaches to establishing a hydrogen supply chain between Germany and Australia. The study will also consider opportunities for trade of technological innovations that could transform the value chains between the countries.

It will help build on existing hydrogen collaborations Australia has with Japan, the Republic of Korea and Singapore.

*CompositesWorld.com article used with permission.

Nov 2020